He Built Foldable Homes That Unpack in a Day

Rohan Kari designed a house that literally folds to one-third its size, ships almost anywhere, and sets on a foundation in a single day. It started with a problem he couldn’t ignore—and turned into a system that could change how housing reaches the hardest places.

The Moment That Sparked the Idea

On a trip to his father’s village in India, Rohan walked through streets where families needed homes fast and options were thin. That’s where the question took hold: how do you deliver a real, durable home to places built far from supply chains?

Remote and rural communities don’t get the same menu of housing choices as big cities. He came back determined to design something that could actually reach those places—and arrive ready to live in.

The Problem That Almost Stopped Everything

Prefab sounded perfect until the shipping math hit. Traditional modules haul empty space—four walls, a roof, and a whole lot of air—so costs and waste spiral.

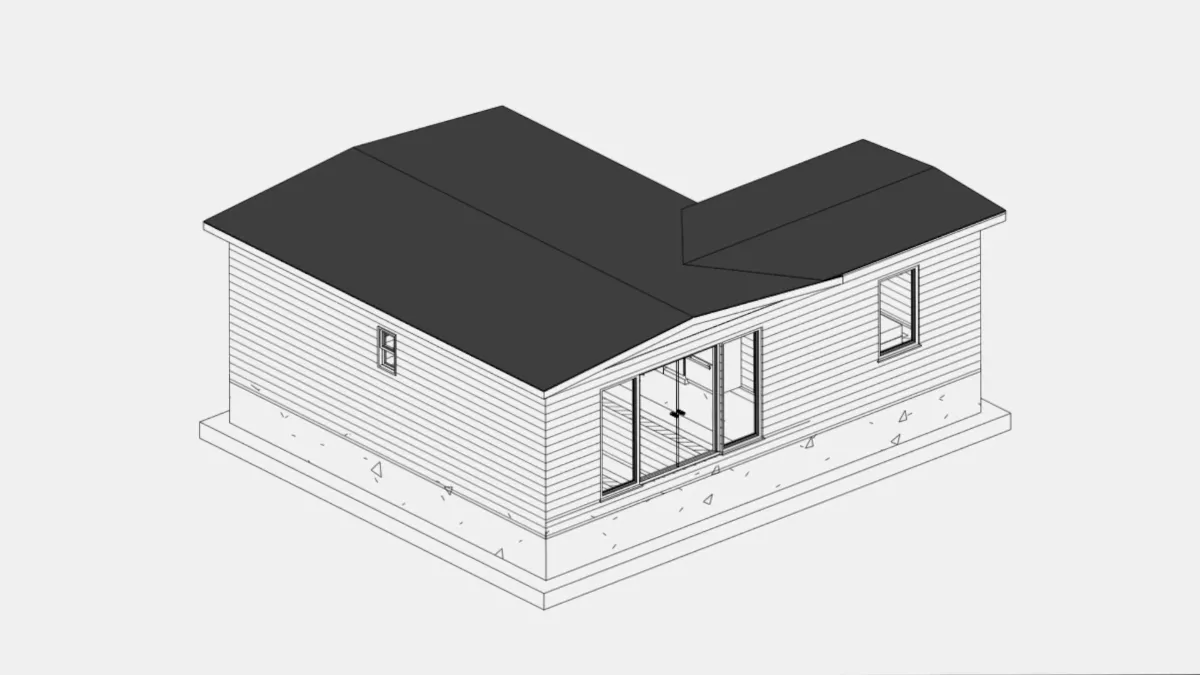

So he flipped the problem. The walls collapse inward, the volume shrinks to one-third, and suddenly the truck carries panels instead of air. It’s simple on paper, but the effect changes the entire cost and carbon story.

How He Actually Solved It

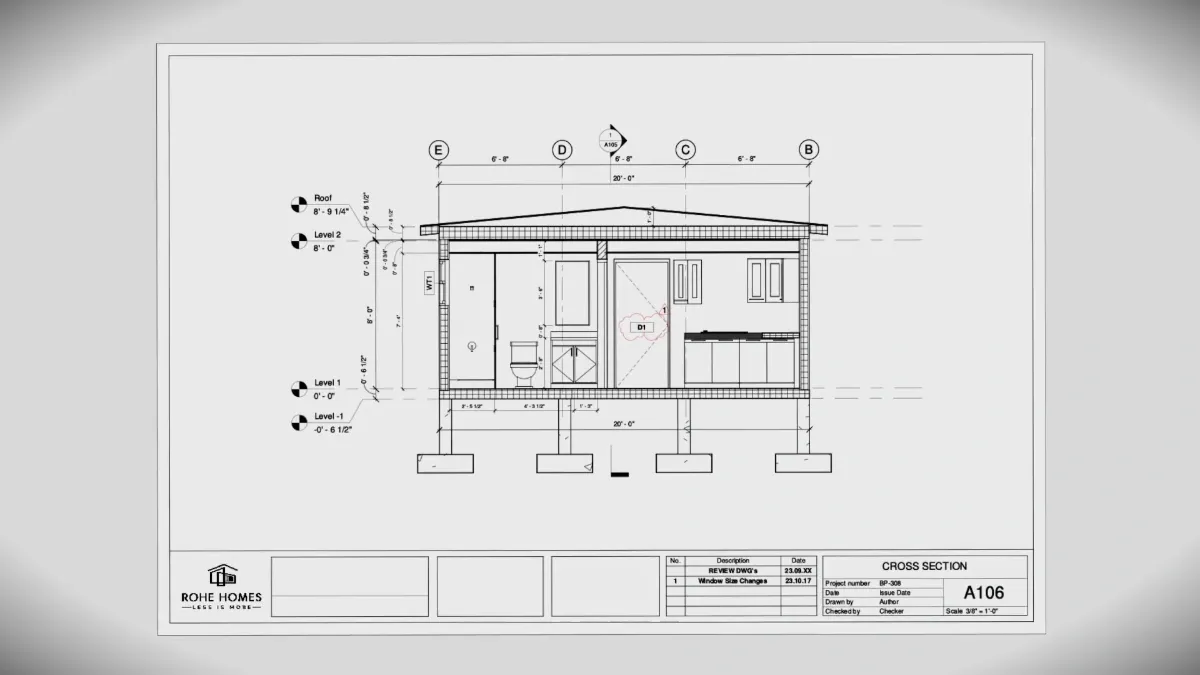

Delivery day moves fast. A crane lifts the compact unit, drops it on the prepared foundation, and crews unfold it like origami. Four hours to open and secure, four more to seal every seam.

Specialized tapes, gaskets, and weather membranes close up the folding joints so water can’t find a path in. By sundown, the shell is weatherproof and ready for finish work.

The trick that makes the whole thing work: engineered hinges that carry serious weight through repeated folds. They look modest but they’re doing heavy lifting, literally.

Each wall panel clocks in around a thousand pounds. The structure mixes dimensional lumber with PSL beams and mass timber, built to stay stiff through the fold-and-unfold cycles.

Insulation is baked in with structural insulated panels, tuned to the climate where the home will land. Higher values for colder zones, scaled back where winters are mild.

They’ve put prototypes through all four seasons and are modeling performance for far-north conditions. The goal: keep it efficient even near the top of the map.

Why This Actually Works Almost Anywhere

The homes are all-electric, using heat pumps and electric baseboard to heat and cool without gas lines. It’s a plug-and-live approach that keeps setup clean.

Foundation choices flex with the site—concrete perimeter walls where you can pour, sono tubes or helical piles where you can’t. That adaptability is a quiet superpower.

Transport is the other superpower. Folded units ride on flatbed trucks to suburbs and towns without drama.

Need to jump a stretch of coastline or reach an island? Barge it. The footprint stays tight, so loading is straightforward.

Long reach across land? Rail works too, expanding the radius without blowing the budget.

For the truly remote, even planes are in play. That opens doors for communities you normally only reach a few months a year.

Who These Homes Are For

Urban folks slot them in as laneway or backyard homes, filling in the gaps cities never used well. It’s a tidy way to add gentle density.

First Nations communities can bring in dignified, permanent housing without waiting on long, fragile supply lines. The logistics bend to the land instead of the other way around.

Disaster recovery is where the speed really matters—fire or flood hits, and a day later a family can have a dry, secure shell to start rebuilding life.

The Part That Really Surprised Me

The smallest model, the Lotus Mini, packs a one-bedroom, one-bath layout into 530 square feet—compact but livable for one or two people. It’s a real home, not a stopgap.

Move up to the Lotus Extra and you get two bedrooms and one bath in 630 square feet, enough room for three or four. The footprint stays modest; the layout does the heavy lifting.

The Lotus Rancher pairs two units into a 1,050-square-foot, three-bed, two-bath home with a full kitchen. It’s the family-size version without the long build.

Pricing is upfront: a lockup-ready shell starts around $125,000 CAD, including structure, windows, MEP rough-ins, roofing, and exterior weatherproofing. That’s the hard part done.

Fully finished—with appliances, flooring, baseboards, casings, and bathroom tile—lands near $200,000 CAD. Owners can lean on local builders or handle finishing themselves if they’ve got the chops.

In the factory, each unit takes about six weeks right now, and the timeline keeps dropping as the team refines the process. Volume is the current bottleneck; efficiency is the lever.

The big picture is simple: fold for transport, unfold for life. It’s a clean answer to a messy problem, built to go where housing rarely can.