The Earthship That Grows Food Indoors — Tires, 10 kW Solar and Cisterns

Walk into the great room and the big south-facing greenhouse sits beside the kitchen and living area.

First Glance — The Great Room & Passive Solar

The design uses passive solar to charge the concrete floor and back wall so the house stores heat like a battery.

The floor feels cool in summer because the high sun angle misses the thermal mass and the cement stays shaded.

When winter sun is low it pours heat onto that same floor and the buttresses, charging stored warmth for nights and cloudy days.

Those buttresses are structural and thermal — cement supports that also soak up sun energy and release it slowly.

The result is steady temperatures underfoot and fewer big swings between day and night.

Growing Inside — Planter Cells and Greywater Reuse

Food production is built into the footprint with two indoor planter cells running along the greenhouse edge.

These planter cells collect greywater and let plants draw moisture up from a sand layer through capillary action.

Transparent tubes show the water level in each cell so management is obvious at a glance.

Below the soil sits a foot of sand, filter cloth and gravel that holds greywater before it drains to the septic field, reducing wasted fresh water.

That passive irrigation means once plants are established they rarely need supplemental watering, which is ideal for kitchen herbs and salad greens.

Having fresh produce steps from the kitchen cuts trips to the store and turns the greenhouse into a working pantry.

Water Systems — Catchment, Cisterns and Backup Options

Rainwater from the roof is routed into buried cisterns and used primarily to flush toilets, reducing municipal demand.

Toilets normally run off stored roof water, with an easy-switch hookup to town water if tanks run low.

A manual switch lets the plumbing flip from cistern supply to town supply for reliability during dry spells.

That redundancy mirrors the heating backup strategy: multiple ways to keep systems working when one source dips.

The buried cisterns sit a few feet underground and are insulated to protect stored water and conserve space on the lot.

Together, catchment plus greywater reuse form a closed-loop approach that stretches every drop.

Heat & Comfort — Wood Boiler, In-floor Radiant and Cooling Tubes

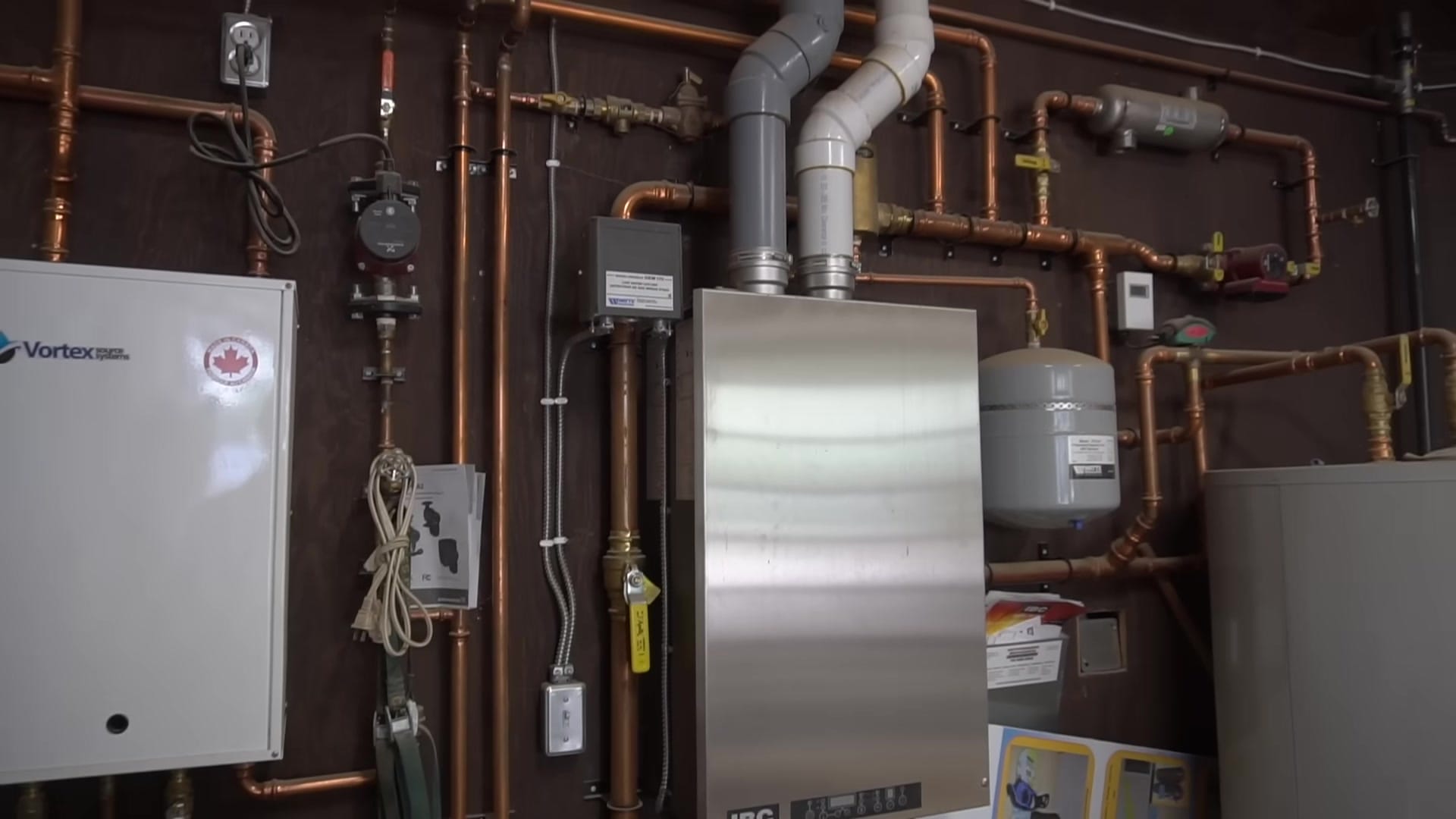

The mechanical room houses a wood-fired boiler that heats water for in-floor radiant loops and domestic hot water.

Firing the boiler aims for tank temperatures around 120–150°F so zones can be fed on-demand.

Heated water is routed through six zone jets to push warmth into different areas as thermostats call for it.

If wood isn’t in use an on-demand propane system will kick in to maintain floor charging and hot water without interruption.

Because the floors are thermal mass, they work with solar gain — sun plus boiler equals a long, steady release of heat.

The system balances passive design and active fuel so comfort stays predictable across Ontario seasons.

Power & Finances — 10 kW Solar, Grid Feed and Payback

A 10 kW solar array sits near the house with a short, direct wire run to the inverter and grid feed.

Short wire runs save on expensive cabling and reduce energy loss between panels and electronics.

The inverter sends surplus electricity back to the grid under a buy-back program that paid roughly $0.28 per kWh at one point.

That rate combined with lower retail purchase costs means the owner receives monthly payments that offset bills and speed payback.

Estimated payback for the panels sits in the 10–15 year window depending on incentives and actual production.

Upfront costs included racking and a bespoke angle, so the system was sized and sited for long-term returns.

Building Materials & Lessons — Tires, Reclaimed Wood and Labour

The walls are formed from over a thousand repurposed tires packed and plastered, and a truth window exposes that tire work.

That truth window provides a clear look into the tire-and-cement backbone used to hold earth back and create thermal mass.

Tire collection and pounding is labour-intensive — sourcing and prepping tires took months of hands-on work.

Interior cladding avoids full cement finishes and instead uses reclaimed pine off-cuts to create a log-home feel without losing the shell’s function.

The build proves recycled materials can perform, but they demand time, sweat and coordination; collecting and pounding tires alone often adds weeks to the schedule.

In return, the structure is durable, hugely insulated by earth, and built around systems that prioritize self-reliance and low operational cost.