This Company Transforms Shipping Containers Into Luxury Homes

Welcome to the fascinating world of Storstac in Toronto, where ordinary shipping containers are transformed into extraordinary living spaces that will completely change how you think about home construction.

The company has mastered the art of converting these standardized steel boxes into stunning homes, additions, cottages, bunkies, man caves, and mobile offices that rival traditional construction in both beauty and functionality.

Anthony, the visionary behind these incredible transformations, explains his passion for modernist architecture and how these square steel boxes perfectly complement contemporary design aesthetics. A quality paint job on these containers creates a striking appearance that lasts for years, offering both durability and the unique advantage of complete mobility.

These aren’t just any ordinary boxes – shipping containers are precision-engineered steel structures designed to transport goods anywhere in the world safely. The standard dimensions of 20 and 40 feet provide the perfect foundation for living spaces, though specialty containers ranging from 10 feet up to 53 feet offer even more creative possibilities.

The secret to their incredible durability lies in their construction from Corten steel, a remarkable weathering steel that actually grows stronger over time. What appears to be rust on the surface is actually a protective patina that shields the steel underneath, allowing these containers to withstand harsh sea conditions without deteriorating.

Step inside Anthony’s crown jewel project – the New Old Stock man caves that now grace Downtown Los Angeles with their ultra-luxurious appointments. These aren’t your typical recreational spaces; they feature Spanish Cedar, Kolkata marble showers, off-grid water systems, and solar panels that make them completely self-sufficient.

The groundbreaking Harlem House project represents Toronto’s first container extension, showcasing how seamlessly these steel structures can integrate with traditional architecture. The result is a stunning fusion that demonstrates the versatility of container construction while maintaining architectural harmony with existing structures.

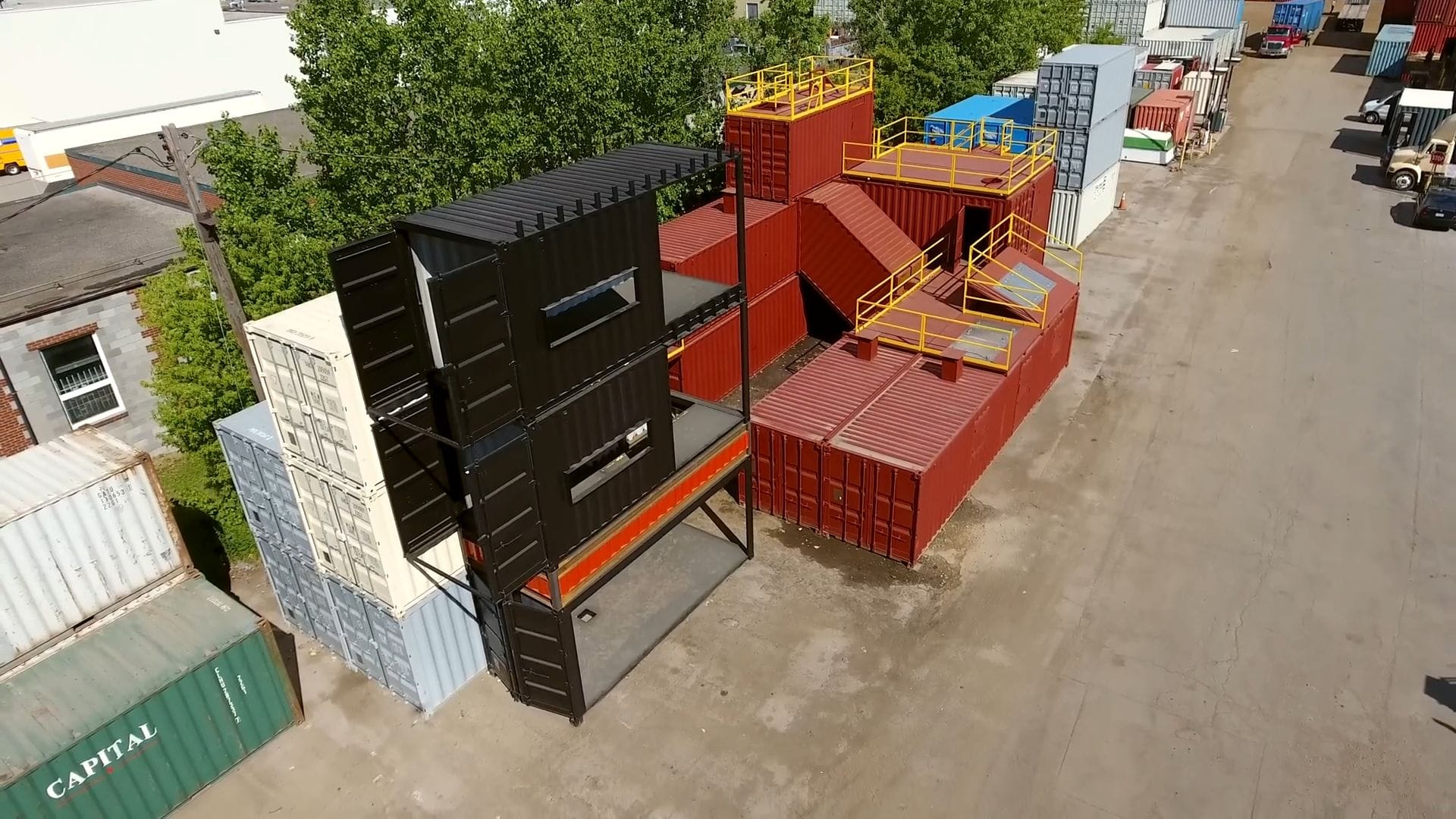

Marvel at the impressive Rogers shipping container Fan Hub, an architectural feat featuring three containers on the bottom level in a fully open concept design. Above, a single container cantilevers 10 feet over the right side, crowned by an expansive 740 square foot patio deck that creates an impressive outdoor entertainment space.

Even the smallest spaces receive the full luxury treatment, as evidenced by the charming 10-foot container bunky built for a client in Tiny, Ontario. This compact 10×8 foot structure proves that size doesn’t limit comfort, featuring full insulation, beautiful finishes, and an elegant glass sliding door that floods the interior with natural light.

The choice between new and used containers depends entirely on the intended purpose, with all containers originating from China regardless of their condition. Used containers typically serve shipping duties for 10 to 20 years, traveling by trains, planes, and trucks across the globe before finding new life as building components.

For residential applications, new containers are always the preferred choice since they’ve only been loaded once before reaching their destination. The concern with used containers lies in their unknown shipping history – without manifests to track their contents, these containers could have transported anything from baby products to nuclear waste over their decades of service.

The modification process begins with precision cutting of all openings for doors, windows, vents, and louvers, each carefully framed with steel for structural integrity. The interior work follows traditional construction methods with framing for walls and ceilings, electrical roughing, and a trip to the paint shop before final finishing touches bring the vision to life.

The beauty of container construction lies in its off-site fabrication capability, allowing complete structures to be delivered and installed in just one day. Imagine going to sleep with just a foundation and waking up to a complete structure – this instant deployability makes container homes perfect for tight construction schedules.

The permitting process for container homes follows exactly the same procedures as traditional construction, requiring architectural drawings and city approval to ensure compliance with Ontario building code. While some projects may require revisions, the structural integrity of steel containers often simplifies the approval process compared to conventional construction methods.

The main challenge lies in the specialized steel work required for exterior modifications, making these projects less suitable for complete DIY enthusiasts without welding experience. However, the biggest hurdle often comes from neighbors who may initially resist the industrial aesthetic, though properly executed projects typically win over even the most skeptical observers with their stunning final appearance.